INSTALLATION AND MAINTENANCE

Maintenance method of mounted ball bearing units

Due to high quality grease filling and sealing with high performance, FSB mounted ball bearing units can be used without oil under normal operating conditions.

However, during the operation of severe environment with high temperature, heavy dust and water, the grease will deteriorate, resulting in poor lubrication, so appropriate periodic inspection shall be carried out to prolong the service life of the bearings.

Periodic inspection of the bearing is through checking the appearance and operating state to judge if bearing is abnormal.

The main abnormal contents and causes found in periodical inspection of bearings are as follows:

The main abnormal contents and causes found in periodical inspection:

Abnormal contents

| Abnormal content | Causes |

| Excessive torque | 1. Deterioration of lubricating grease |

| 2. Grease is excessively supplemented, resulting in the contact between seal and retainer | |

| 3. Retiner becomes deformed and contact with seal | |

| 4.The abnormal load caused by the elongation of shaft | |

| Abnormal sound and vibration | 1. The looseness of set screws of inner ring of bearing or mouted bolts of bearing housings. |

| 2. Due to creep or abrasion, the mating surfaces between the shaft and the inner ring of the bearing are worn out | |

| 3. Foreign bodies intrude into the inside of bearings | |

| 4.The rolling surface of the bearing is damaged because of rolling fatigue | |

| 5.Excessive load leads to indentation on the raceway of the bearing. | |

| 6.The shaft is bent or bent too large | |

| Abnormal temperature rise | 1. Deterioration of lubricating grease |

| 2. Grease is excessively supplemented, resulting in the contact between seal and retainer | |

| 3. Retiner becomes deformed and contact with seal | |

| 4. The looseness of set screws of inner ring of bearing or lock nut | |

| 5 .The abnormal load caused by the elongation of shaft | |

| 6.The rolling surface of the bearing is damaged because of rolling fatigue |

If the bearing is abnormal through regular inspection, measures should be taken promptly and implemented. Bearing should be replaced in time to avoid the damage to other parts and major accidents.

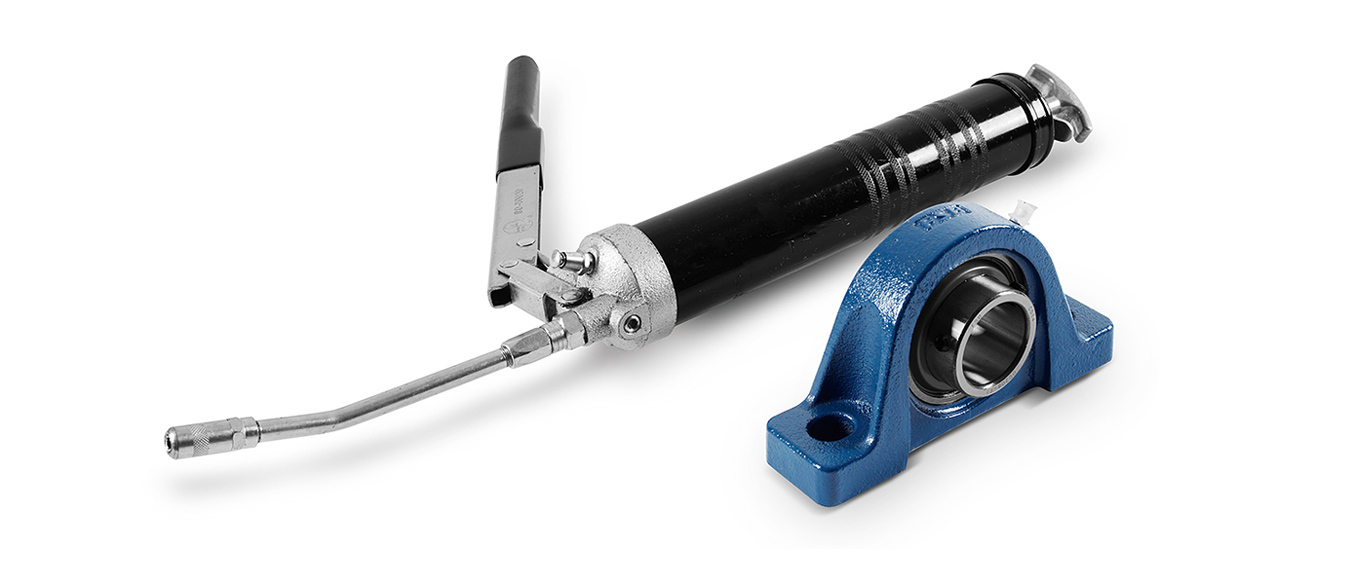

Grease supplement

FSB mounted ball bearing units are oil supply type, which can be supplemented the same type of grease regularly to keep the normal lubrication state, thereby prolonging the service life of the bearing.

The recommended intervals for grease supplement for bearings

| Operating temperature | Intervals of time for grease supplement | Using bearing | |||

| > | ≤ | Very clean | Dusty | Dusty, splashing mud | |

| - | 50 | 3 Months | 2 Months | 1 Month | Ordinary type |

| - | - | No greasing | 1 Year | 4 Months | |

| 50 | 70 | 1 Year | 4 Months | 1 Month | |

| 70 | 100 | 6 Months | 2 Months | 2 Weeks | |

| 100 | 120 | 2 Months | 2 Weeks | 5 Days | Heat-resistant type |

| 120 | 150 | 2 Weeks | 5 Days | 2 Days | |

| 150 | 180 | 1 Week | 2 Days | 1 Day | |

The recommended grease supplement amount for mounted ball bearing units

| Bore model | Grease supplement amoun,g | ||

| Diameter series | |||

| 2 | X | 3 | |

| 01 | 1 | - | - |

| 02 | 1 | - | - |

| 03 | 1 | - | - |

| 04 | 1 | - | - |

| 05 | 1 | 1.5 | 2.0 |

| 06 | 1.5 | 2.0 | 3.0 |

| 07 | 2.0 | 2.5 | 3.5 |

| 08 | 2.5 | 3.0 | 5.0 |

| 09 | 3.0 | 3.5 | 6.5 |

| 10 | 3.5 | 4.5 | 8.5 |

| 11 | 4.5 | 6.0 | 12 |

| 12 | 6.0 | 7.0 | 15 |

| 13 | 7.0 | 8.0 | 18 |

| 14 | 8.0 | 10 | 22 |

| 15 | 10 | 12 | 26 |

| 16 | 12 | 15 | 30 |

| 17 | 15 | 18 | 35 |

| 18 | 18 | 22 | 40 |

| 19 | - | - | 48 |

| 20 | 25 | 30 | 62 |

| 21 | 30 | - | 70 |

| 22 | - | - | 82 |

| 24 | - | - | 99 |

| 26 | - | - | 127 |

| 28 | - | - | 152 |

Note 1) the basic model of the bearing consists of the subsequent bore model of diameter series.

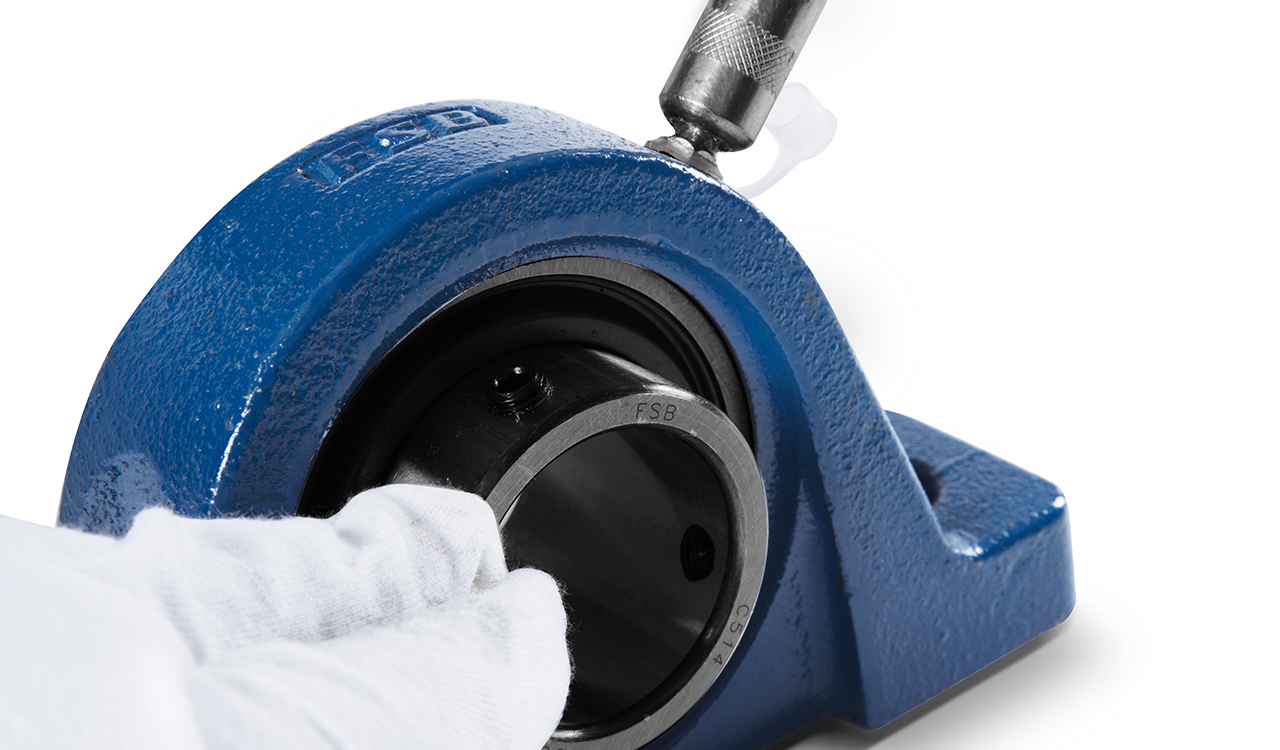

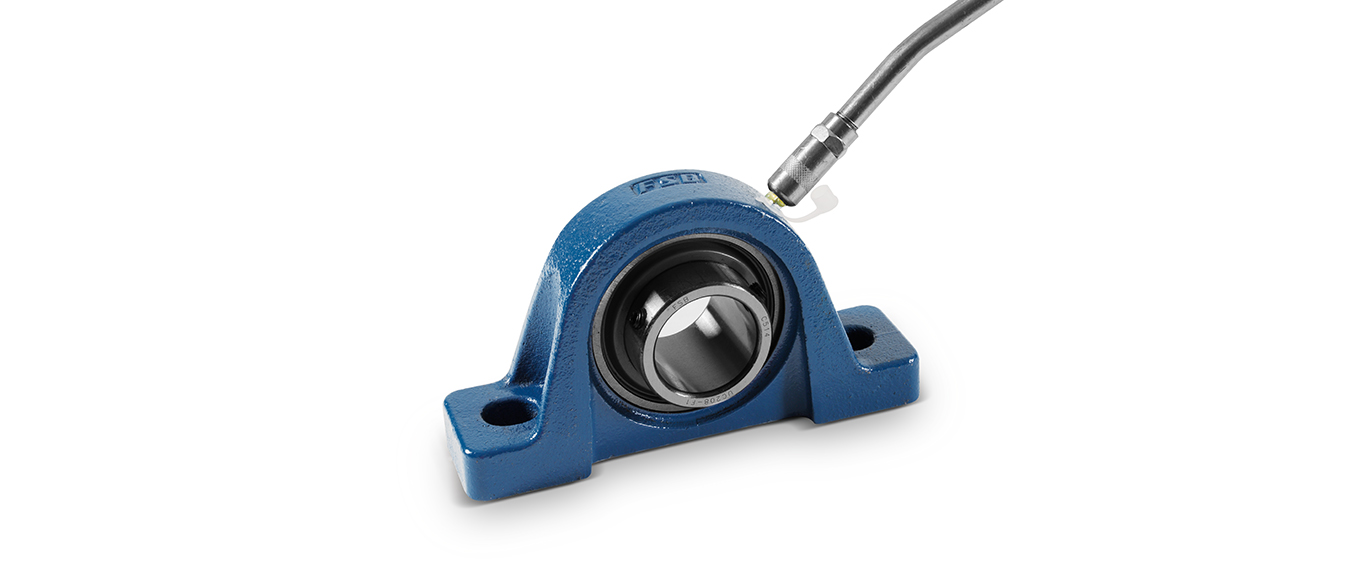

The grease is supplemented by means of the grease nipple on the bearing housings and grease gun:

1. Clean the surrounding areas of grease nipple and cap, open the grease cap and clean the grease nipple

2. Clean grease gun and fill clean grease.

[Note]: It is advised to rotate the shaft by hand (or rotate the mounted ball bearing units at low speed) while the mounted ball bearing units are supplementing the grease. This allows the new grease to be evenly added to the inside of bearing.

3. Clean the remaining grease in the grease nipple and the surrounding areas and reinstall the grease cap to the grease nipple.

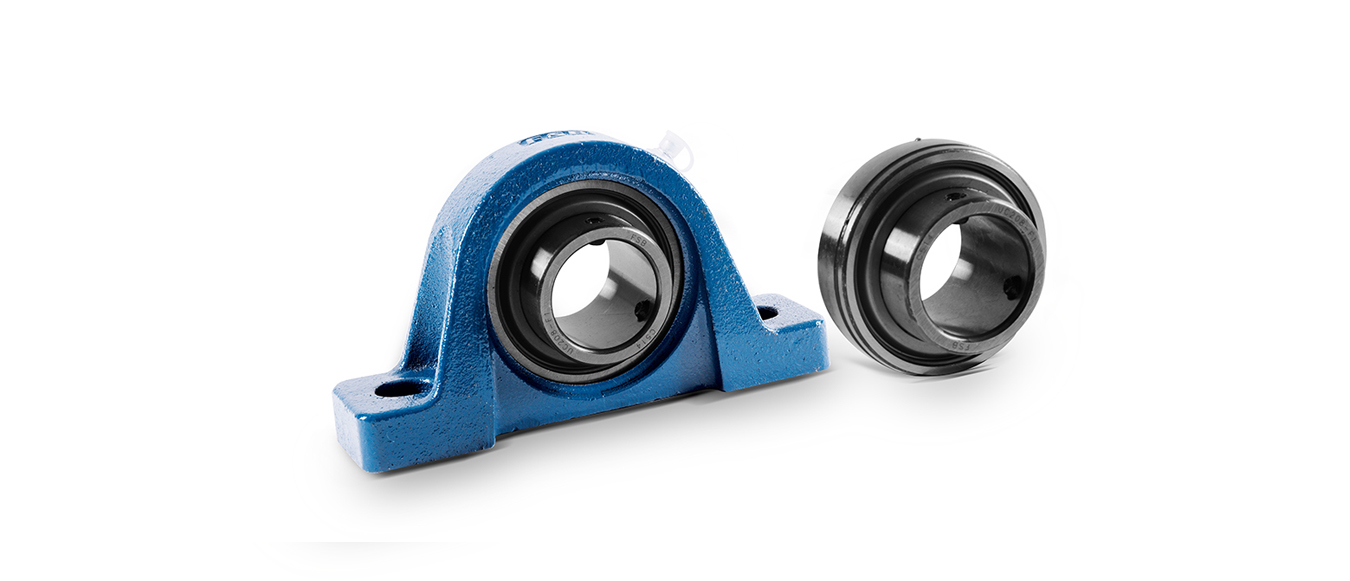

Replacement of bearings

The bearings and housings of FSB mounted ball bearing units are interchangeable; if the bearing is abnormal, it can continue to use by replacement of bearing.

The replacement process of mounted ball bearing units is as following:

1. Unload the mounted ball bearing units from the shaft and base.

2. Screw in set screws until the heads are lower than the outer diameter surface of the inner ring of the bearing. Prevent the heads of set screws from interfering with the housings when the bearing is removed.

3. Rotate the bearing 90 degrees at the level with hammer handle and so on.

4. Take out the bearing from the mounting groove of the bearing housings and install the new bearing in the opposite process of disassembly.

Take out the bearing from the mounting groove of the bearing housings and install the new bearing in the opposite process of disassembly.