Agricultural Machinery Solutions

The status analysis of agricultural machinery bearings

Good sealing performance and high strength sealing structure requirements

Long-term exposure to dust, debris, muddy, rain and other environments agricultural machinery continuously vibrates for the whole operation season and bears the impact of crop straw. Pollutants invasion or grease loss caused by seal failure always leads to premature agricultural bearings failure and equipment out of work.

Easy installation and maintenance free

For example, the installation space of the peeling machine is very narrow and the working environment is very bad, which requires to reduce the need for maintenance and lubrication.

High Reliability

During the harvest season, the failure of agricultural machinery and unplanned downtime will cause huge production losses.

The seasonality of agricultural machinery

After standing idle for months, the combine harvesters start to work intensively day and night.

Clutch bearing under the impact load

The instant start and stop of clutch will cause very high impact load to the bearing and the running speed is relatively high.

Limitation of installation space

Due to the limitation of installation space, bearings for some parts have to be specially designed.

The solutions of agricultural machinery from FSB

We enter the farmland with equipment manufacturers and discuss the challenges they face and the questions they are concerned about. Through working closely with equipment manufacturers, we develop solutions towards the practical problems to meet the growth requirement of modern agriculture.

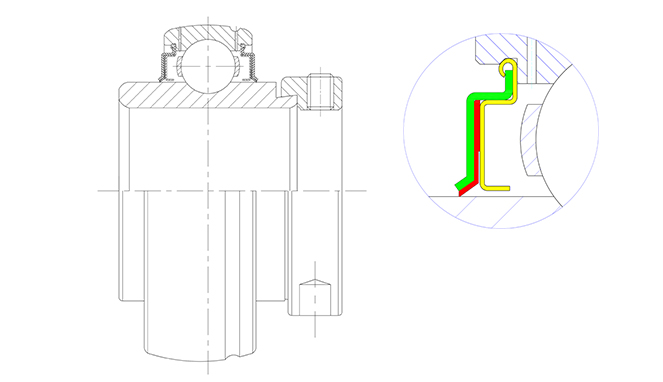

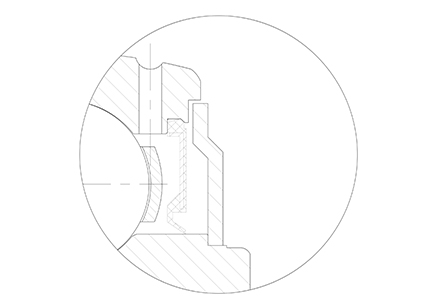

The combined sealing structure with high strength and sealing performance

The concept of designing the sealing with high accuracy and precision can operate F combined seal structure reliably under various weather conditions.

1.The frame and outer ring are rigid riveting so that the sealing will not be removed because of vibration or excessive grease injection.

2.Two layers of steel skeleton and integral sealing structure significantly improve the strength of the sealing.

3.The outer cover extends to the width direction of the sealing, which ensures the protection of the sealing lip and prevents mechanical damage.

4.The sufficient storage space between the elongating and inclined steel plates extends the bearing maintenance cycle.

5.The coaxiality of the sealing contact surface means that the sealing effect and service life have been significantly improved.

Overall enhancing design of housings

In view of the high-intensity working environment of agricultural machinery, the housings adopt the overall enhancing design to withstand continuous vibration and impact load.

Strict control of processing

Equipped with imported high precision testing equipment, the bearings are processed with full automatic processing equipment and controlled by the zero defect according to the USA MIL-STD 1916 sampling standard, which ensure the safety and reliability of the product.

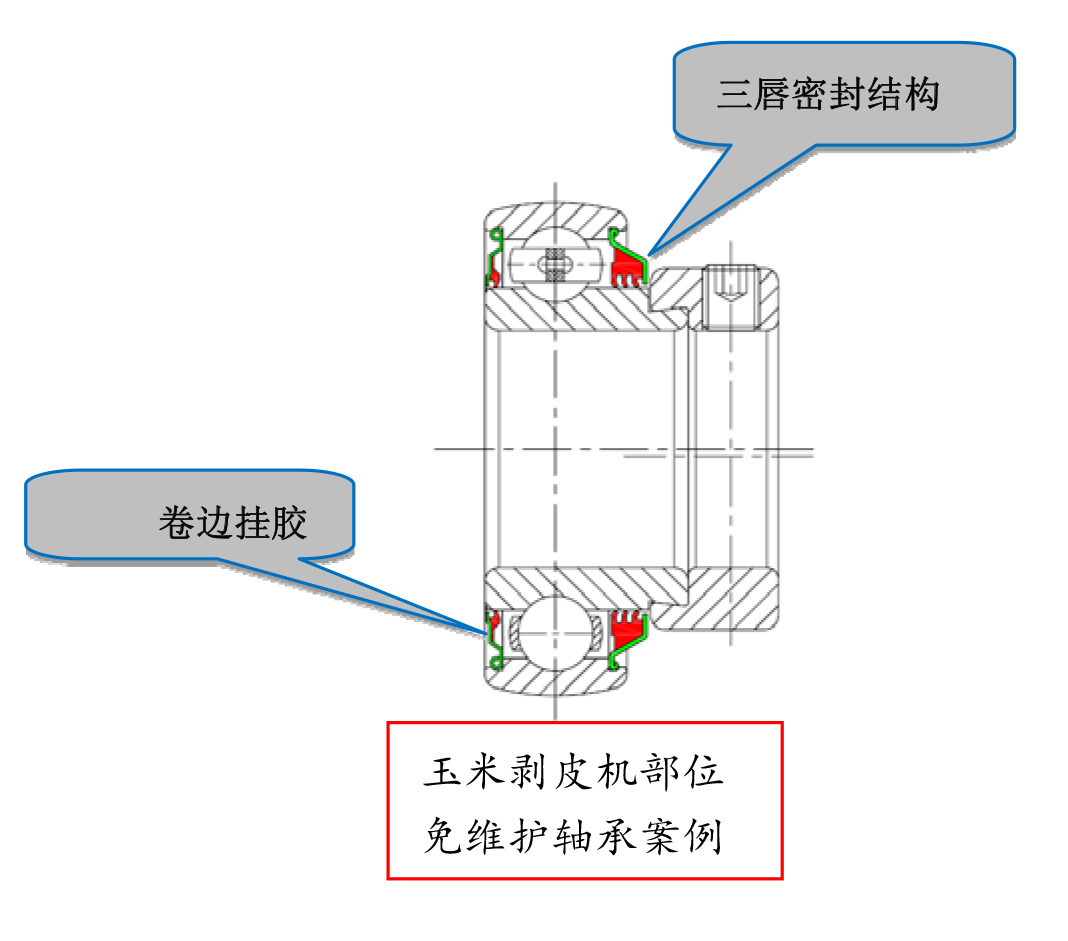

Maintenance-free design

Given that some parts of agricultural machinery suffer from very bad working environment, FSB raises the design concept of maintenance free.

According to different applications of agricultural machinery, we have developed corresponding products to meet your needs.

According to different applications of agricultural machinery, we have developed corresponding products to meet your needs.

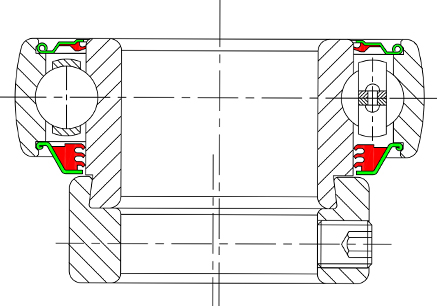

Bearings withstanding high load, high speed and high pollution.

The internal structure of the bearing is optimized and adjusted and the sealing structure adopts : The mounted ball bearing units with the unique labyrinth sealing structure of the high strength retainer plus seal and ductile iron housings can still keep high speed and smooth operation under high load and high pollution.

High Torque Bearing

We use the reliable locking structure of the hexagonal hole and prevent the relative rotation between the bearing inner ring and the shaft through the geometric locking effect.