Packaging Machinery Solutions

The status analysis of packaging machinery bearing

Packaging machinery plays a very important role in the packaging industry and bearing as the key component of the packaging machinery, its adaptive selection has a profound impact on the whole industry.

Requirement of compact structure

The limitation of the packaging machinery structure requires that the bearing should withstand enough load in the limited installation space.

Wider Temperature Applicability

The working temperature of the local position of packaging equipments, such as stowing machinery, filling machinery, sealing machinery, changes at any times, which requires the bearing to operate safely and reliably in this environment.

Requirement of long-term and smooth operation

During the packaging process, the unplanned downtime will limit the production efficiency and even affect the delivery time, which requires the bearing performance is safe and reliable.

Requirement of Corrosion Resistance

It requires bearings to be with good corrosion resistance in the corrosive special packaging environment of humid, salt spray, weak alkali or weak acidity.

Packaging environment requires low pollution.

During the operation, the bearings are required to have good sealing performance to avoid leakage of grease and polluting the products and packaging; at the same time, it is necessary to effectively prevent debris from intruding into the bearing.

High maintenance costs for special occasions

In the packing process of some special occasions, the lubricating grease should be supplemented regularly, which not only leads to the increase of maintenance cost, but also the risks of leakage of grease and packing pollution.

The solutions of packaging machinery from FSB

With technical exploration in the industry and decades of technical experience in the field of equipment manufacturers and end users, we provide you with a comprehensive solution to reduce economic losses due to bearing failure.

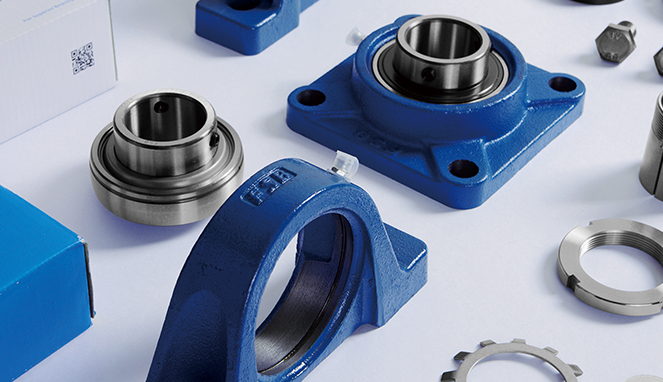

Varied Product Structure

To meet your best design purpose, FSB owns various shapes and specifications of mounted ball bearing units. If you have special design requirements, please kindly contact with FSB and we will quickly design and deliver the satisfactory product to you according to your needs.

Long-term and smooth operation

The inner structure of the bearing is optimized and the machining precision is strictly controlled. We choose the high quality material for housings and process them through high level casting technology and special processing equipment, so that the bearing will not suffer from the abnormal load, thus improving the overall safety performance of the bearing and ensuring the long-term and smooth operation with low noise.

Unique Sealing Performance

We develop different sealing structures for different applications. In the case of satisfying the working conditions, it can effectively prevent the products getting polluted due to grease leakage and avoid impurities invading the inner of bearing as well.

Wide Application Temperature

We select the reasonable grease and optimized the bearing inner structure, so that the bearing can be still in the best state in a wide range of temperature change; thus extending the service life of bearing and reducing the cost of maintenance.

Good Corrosion Resistance

For the using environments of humid, weak acidity and basicity and frequent flushing, the bearing surface is specially treated to make it have excellent corrosion resistance.

Non-lubricating bearings

For the use of special occasions, the non-lubricating bearings we design eliminate the need for frequent plan of supplementary lubrication and the possibility of grease leakage, which will help the manufacturer to meet the health requirements and obtain 100% operational reliability; at the same time, the safety of the maintenance personnel is improved.