The solutions of transmission system from FSB

The status analysis of transmission system bearing

Requirement of long-term and smooth operation

In the process of material transfer, the unplanned downtime will limit the delivery efficiency of materials, even affect the delivery time or delay the customer's travel, which requires bearings to be with high reliability.

Low pollution in the process of transmission

During transmission, bearings are required to have good sealing performance so as not to pollute the products due to leakage of lubricating grease. Meanwhile, it is necessary to prevent debris from intruding into bearings.

Low Noise

When labors work near to the transmission system, noise will act on the central nervous system of the brain through hearing organs, which is harmful to the physical and mental health of the human being, so it is necessary to effectively control the harm of noise and reduce noise pollution. As the key component of the transmission system, bearings require long-term low noise and smooth operation.

Different use performance is required for special occasion

For example, during the transmission process of materials, the local position of heat treatment equipment is with high temperature, which requires bearings to have good performance of high temperature resistance and operate safely and reliably under this environment. Due to the corrosion of sea salt with high humidity, bearings should own good performance of corrosion resistance during the material transfer process in the port.

Harsh Operating Environment

During the transmission process, the pollutants whether transporting dirt, abrasive coal, metal, cement, or dry and dusty grains, will frequently destroy bearings’ seal, which causes the premature failure of bearing and affects the operation of the whole transmission system.

The status analysis of transmission system bearing

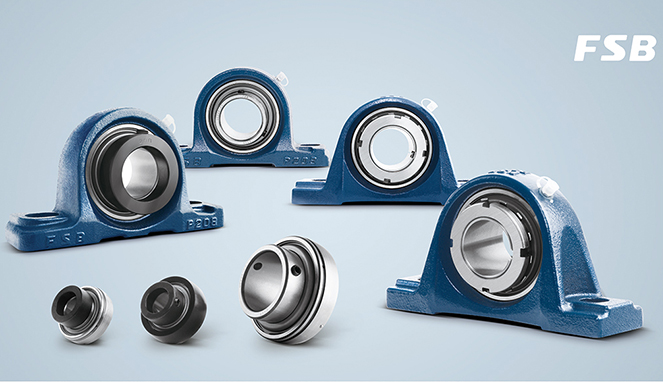

Based on the experience and extensive knowledge of the transmission industry and combined with our products, FSB provides a full range of solutions to the problems you are facing.

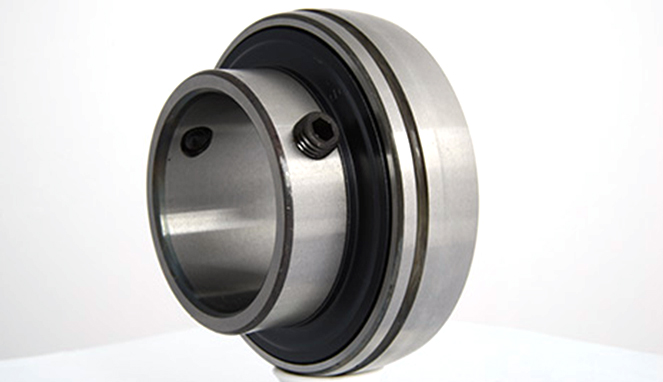

Optimal design of bearing structure and high level machining control

The inner structure of the bearing is optimized and the machining precision is strictly controlled. We choose high quality materials for housings and process them through high level casting technology and special processing equipment, so that the bearing will not suffer from the abnormal load, thus improving the overall safety performance of the bearing and ensuring the long-term and smooth operation with low noise.

Unique Sealing Structure

We develop different sealing structures for different applications, which can effectively avoid impurities invading the inner of bearing and make the whole transmission system run smoothly for long time; At the same time, it can effectively prevent the products getting polluted due to grease leakage.

Good High Temperature Resistance

We choose reasonable grease, suitable sealing material and optimized inner structure of bearing so that the bearing can be still in the best condition in the range of temperature. For the low speed and high temperature using environment, we have developed the floating end bearing to avoid the thermal expansion of the shaft which makes bearing suffer from abnormal load.

Good Corrosion Resistance

On account of the using environments of humid, weak acidity and basicity and frequent flushing, the bearing surface is specially treated to make it have excellent corrosion resistance.

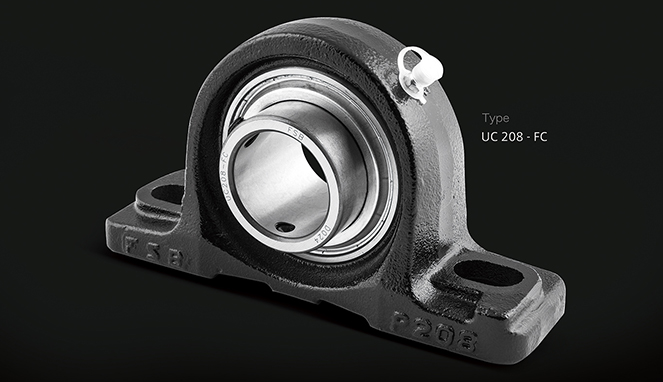

Varied Products Structure

To meet your best design purpose, FSB owns various shapes and specifications of mounted ball bearing units. If you have special design requirements, please kindly contact with FSB and we will timely needs.