Woodworking Machinery Solutions

The working status analysis of woodworking machinery bearings

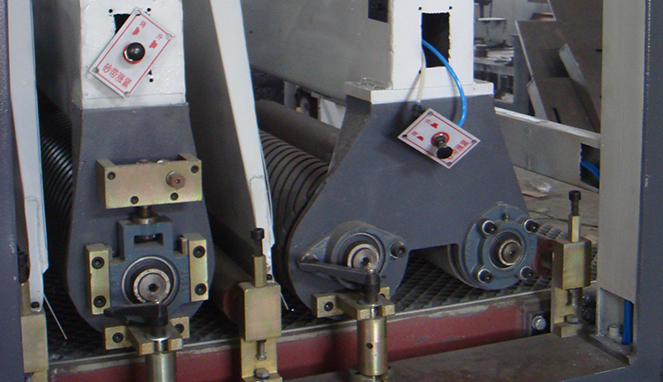

High Rotation

When the bearing of sanding machine is polishing, the rotation speed can reach 2800r/min.

Requirement of long life

It requires long-term trouble-free operation for bearings.

Intermittent Alternating Load

Due to the unevenness of wood while polishing, bearings have to bear intermittent alternating load.

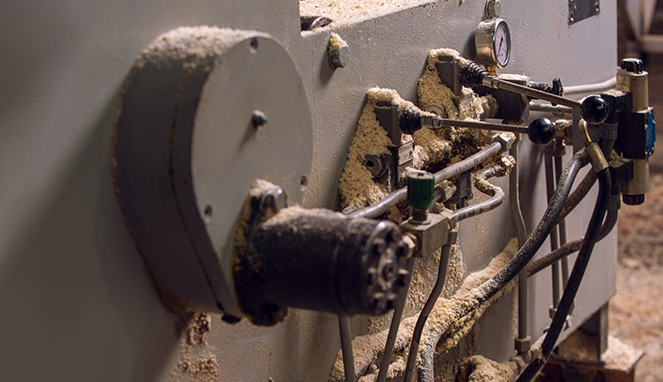

Serious pollution of environment

The working environment of the bearing is very bad because a lot of dust and sawdust will come out during the wood processing.

The solutions of woodworking machinery from FSB

Based on field experience and survey feedback for woodworking machinery, Fushan has developed a series of targeted solutions, including the woodworking machinery bearings.

Bearing Material

FSB adopts domestic high purity bearing steel to improve the bearing stability, which extends the bearing life by more than 30%.

Suitable grease

FSB adopts high quality motor grease and lubrication technology to effectively improve the bearing life and reliability.

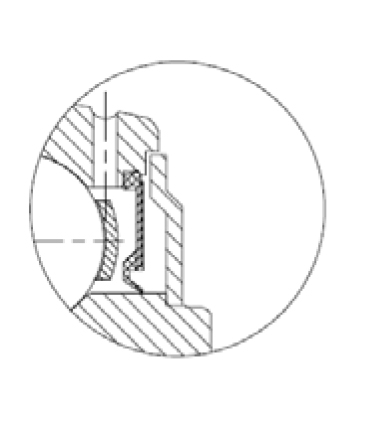

Improved sealing structure

On account of the working conditions of woodworking machinery, FSB has developed a special sealing, which owns the characteristics of light torque, high dust-proof, low looseness and obtains the patent rights. Under the same condition, we have done dust-proof tests for both our product and other bearings of the same size, resulting in 45% better dust-proof performance.

Optimal design of bearing raceway

The optimization and adjustment of the bearing raceway parameters and special processing technology can reduce the friction coefficient of the raceway and improve the reasonable distribution of the lubricating oil in the working process, which makes it maintain effective lubrication and lower noise level at high speed.